Please rotate your screen

vertically to experience.

Please rotate your screen

vertically to experience.

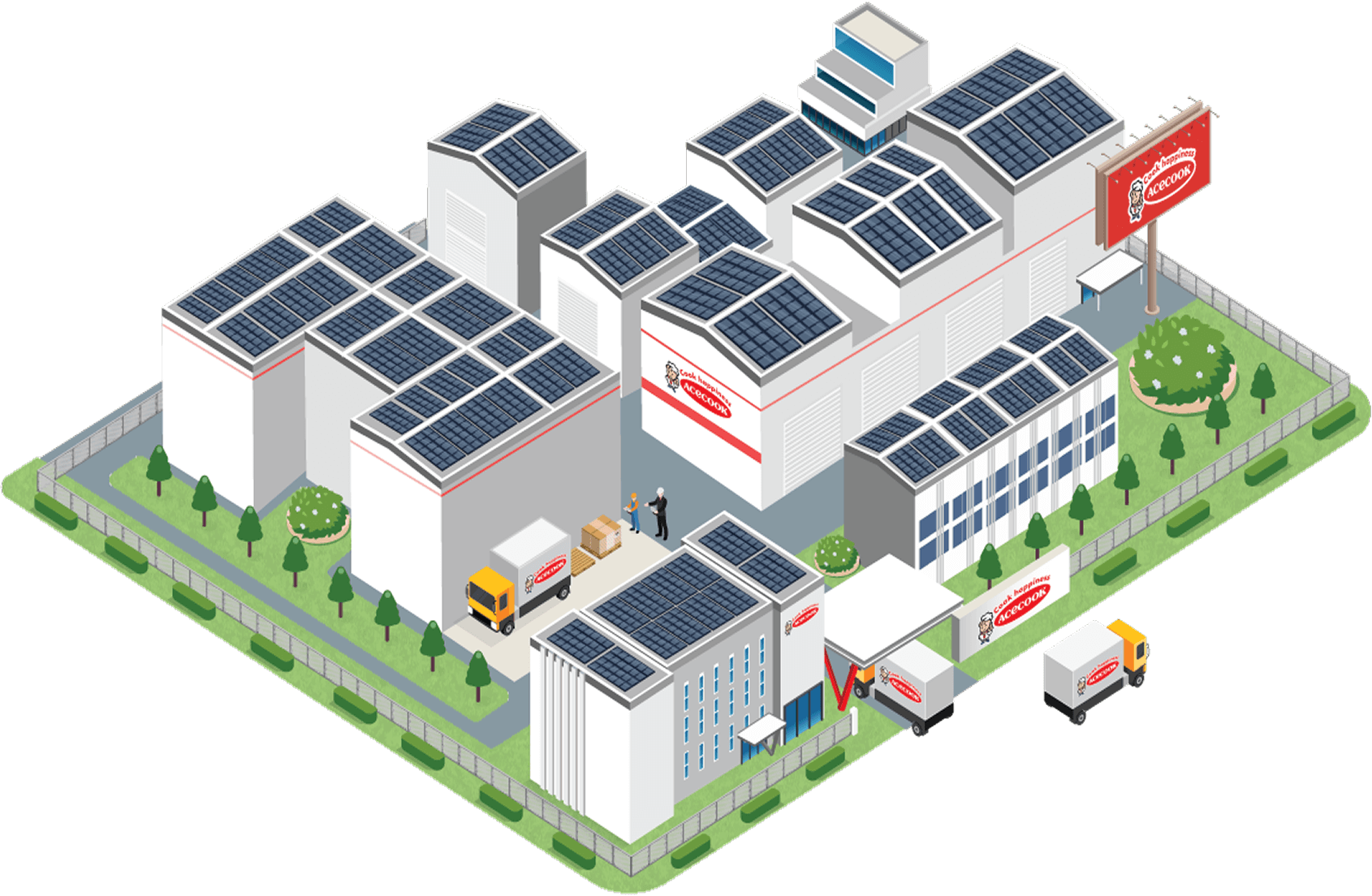

03Acecook Vietnam Factory

A system of modern factories standardized from Japan

Acecook Vietnam currently operates 13 factories and 6 branches nationwide. Each factory is invested with tens of millions of USD, uses automated production lines, and directly transfers technology from Japan. The production process of Hao Hao noodles goes through 11 strict stages: from mixing flour, sheeting, forming strands, steaming, drying/frying, cooling, seasoning, to packaging, quality control, and dispatch. On average, the production line can produce up to 600 noodle packs per minute.

The entire production process is strictly quality-controlled according to international standards such as: the HACCP (Hazard Analysis and Critical Control Points) system; the BRCGS (Brand Reputation Compliance Global Standards); the IFS Food (International Featured Standard Food) for quality and food safety assessment; and the ISO 22000:2018 international standard for food safety management systems. In particular, Acecook also invested in an ISO 17025:2017 compliant laboratory, recognized by the Bureau of Accreditation (BoA) under the Ministry of Science and Technology, to inspect raw materials and finished products in accordance with the regulations of Vietnam and exporting countries.

Acecook is making comprehensive and strong investments in green transformation. Currently, 54% of Acecook's factories use biomass fuel; the goal is to increase this ratio to 80% by 2030. Additionally, the company actively improves products to minimize environmental impact, with 90% of cup, bowl, and tray noodle packaging now switching to eco-friendly paper packaging.